In recent years, sustainable practices and eco-friendliness have become paramount in various industries, including construction and interior design.

As the world faces environmental challenges, there is a growing demand for eco-conscious materials that do not compromise on aesthetics and quality.

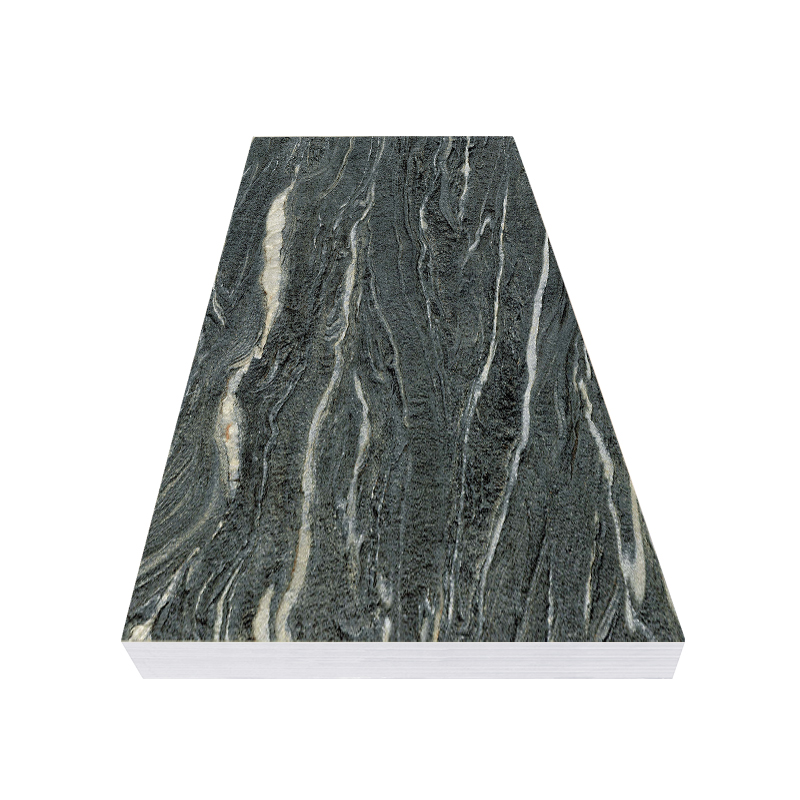

One such material that has gained popularity in the interior design and architectural community is PVC marble sheets.

These sheets mimic the appearance of natural marble but offer distinct advantages, particularly in their eco-friendliness.

This essay explores the sustainable aspects of PVC marble sheet manufacturing, highlighting how these products contribute to a greener future. From raw material selection to the production process,

this essay will delve into the eco-friendly features of PVC marble sheets, demonstrating why they have become an appealing choice for environmentally-conscious consumers.

Recyclable Raw Materials

The foundation of any eco-friendly product lies in the materials used for its production.

PVC marble sheets are primarily made from a combination of polyvinyl chloride (PVC) and natural marble powder.

Both materials possess eco-friendly characteristics that contribute to the sustainability of the final product.

PVC, a synthetic plastic polymer, is known for its recyclability. Unlike other plastics that might end up in landfills,

PVC can be effectively recycled and reused in the production of new materials, reducing its environmental impact. When PVC marble sheets reach the end of their lifespan,

they can be recycled into other PVC-based products, minimizing waste and conserving resources.

Additionally, the use of natural marble powder in the manufacturing process enhances the sustainability of PVC marble sheets. Marble,

a natural stone, is a non-toxic and non-polluting material. By incorporating marble waste from mining operations or reclaimed marble from broken or discarded slabs,

the PVC marble sheet industry helps in reducing the environmental burden associated with marble extraction and processing.

Energy-Efficient Production Process

Sustainability also lies in the energy efficiency of the manufacturing process.

PVC marble sheet factories have made significant strides in optimizing their production processes to minimize energy consumption and carbon emissions.

One aspect of their energy efficiency stems from advancements in machinery and technology.

Modern production lines are designed to be energy-efficient, utilizing automated processes that reduce human intervention and energy wastage.

Moreover, some manufacturers have implemented renewable energy sources, such as solar panels and wind turbines, to power their factories partially or entirely.

These initiatives not only decrease the carbon footprint but also contribute to the overall sustainability of the PVC marble sheet manufacturing industry.

Reduced Environmental Impact

Compared to the extraction of natural marble and other stone materials, the production of PVC marble sheets has a significantly lower environmental impact.

Natural marble quarrying involves extensive excavation, which can lead to deforestation, habitat destruction, and soil erosion.

On the other hand, PVC marble sheet manufacturing relies on a more controlled and less invasive process.

The reduced environmental impact of PVC marble sheet production can be attributed to several factors. Firstly,

PVC marble sheets do not require the mining of new resources, as they utilize marble waste and recycled PVC.

This helps conserve natural resources and reduces the need for additional mining activities.

Secondly, the manufacturing process is generally less water-intensive, thereby mitigating the strain on local water sources.

Moreover, the absence of harmful chemicals in PVC marble sheets ensures that no hazardous substances are released during their production, use, or disposal.

This significantly minimizes air and water pollution, making PVC marble sheets a safer and more sustainable choice for interior design projects.

Longevity and Durability

Sustainability is not only about the materials used in manufacturing but also about the lifespan of the end product.

PVC marble sheets are renowned for their durability and longevity, making them an environmentally friendly option for long-term usage.

Unlike natural marble, which may require frequent maintenance and periodic replacement, PVC marble sheets are highly resistant to scratches, stains, and moisture.

This resilience ensures that the sheets retain their appearance and functionality for an extended period, reducing the frequency of replacements and minimizing waste.

In conclusion, PVC marble sheet manufacturing demonstrates an impressive commitment to sustainability through its use of recyclable materials,

energy-efficient processes, reduced environmental impact, and long-lasting properties.

These eco-friendly aspects position PVC marble sheets as an elegant and responsible choice for interior designers, architects, and environmentally-conscious consumers.

As the demand for sustainable materials continues to rise, the PVC marble sheet industry sets an encouraging example for other sectors,

showcasing how elegance and eco-friendliness can go hand in hand to create a greener future.